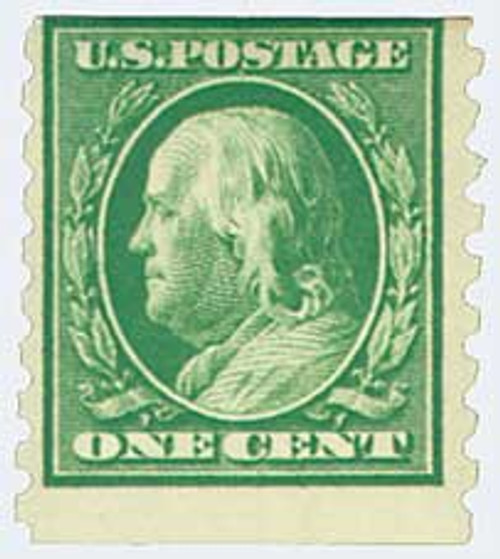

1913 5c Washington, blue

# 396 - 1913 5c Washington, blue

$65.00 - $1,700.00

U.S. #396

1910-13 5¢ Washington Coil

1910-13 5¢ Washington Coil

Issue Date: March, 1913

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 8 ½ vertically

Color: Blue

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 8 ½ vertically

Color: Blue

By 1910, the Bureau found itself producing coiled stamps by the millions. As demand for coils increased, it became apparent that a more efficient and economical means of manufacturing them was needed.

With the old method, sheets of 400 stamps were perforated in one direction and then cut in half. These sheets were then put into a “stripper” and cut into strips of twenty stamps. Workers would then hand-assemble the strips into coils of 500 or 1000. This system required “paste-ups,” in which one strip of twenty had to be glued to another until 25 or 50 strips (depending on whether the coil was to have 500 or 1000 stamps) had been attached. These long, continuous strips were then wound into rolls for use in the vending machines.

Eventually, it was determined that an enormous amount of time could be saved if the sheets were pasted together before being cut into strips. Thus, only one paste-up would be necessary, as opposed to twenty. Because the stripping machines were not equipped to cut through double the amount of paper every twenty stamps, J.E. Ralph designed a new machine.

Designed with stronger cutting wheels, capable of slicing the paper joints, the new machine not only cut the sheets into strips, but also wound the rows into coiled rolls. This invention, in addition to cutting down the time needed to produce coils, also reduced the number of workers by nearly 90 percent! Instead of requiring seventeen workers, as the previous hand-assembling method did, the new machine only needed two operators.

U.S. #396

1910-13 5¢ Washington Coil

1910-13 5¢ Washington Coil

Issue Date: March, 1913

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 8 ½ vertically

Color: Blue

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 8 ½ vertically

Color: Blue

By 1910, the Bureau found itself producing coiled stamps by the millions. As demand for coils increased, it became apparent that a more efficient and economical means of manufacturing them was needed.

With the old method, sheets of 400 stamps were perforated in one direction and then cut in half. These sheets were then put into a “stripper” and cut into strips of twenty stamps. Workers would then hand-assemble the strips into coils of 500 or 1000. This system required “paste-ups,” in which one strip of twenty had to be glued to another until 25 or 50 strips (depending on whether the coil was to have 500 or 1000 stamps) had been attached. These long, continuous strips were then wound into rolls for use in the vending machines.

Eventually, it was determined that an enormous amount of time could be saved if the sheets were pasted together before being cut into strips. Thus, only one paste-up would be necessary, as opposed to twenty. Because the stripping machines were not equipped to cut through double the amount of paper every twenty stamps, J.E. Ralph designed a new machine.

Designed with stronger cutting wheels, capable of slicing the paper joints, the new machine not only cut the sheets into strips, but also wound the rows into coiled rolls. This invention, in addition to cutting down the time needed to produce coils, also reduced the number of workers by nearly 90 percent! Instead of requiring seventeen workers, as the previous hand-assembling method did, the new machine only needed two operators.