1919 1c Washington, gray green, perf 12.5

# 536 - 1919 1c Washington, gray green, perf 12.5

$22.50 - $355.00

U.S. #536

1919 1¢ Washington

1919 1¢ Washington

Issue Date: August 15, 1919

Printed by: Bureau of Engraving and Printing

Method: Offset printing

Watermark: None

Perforation: 12.5

Color: Gray green

The Series of 1919 1¢ Washington produced by offset printing was the result of an experiment by the Bureau of Engraving and Printing. The Bureau was testing the new Rossback perforating machine. The experiment failed, as nearly half the sheets had to be destroyed because of major perforating errors. An estimated 1,386,000 stamps were issued.

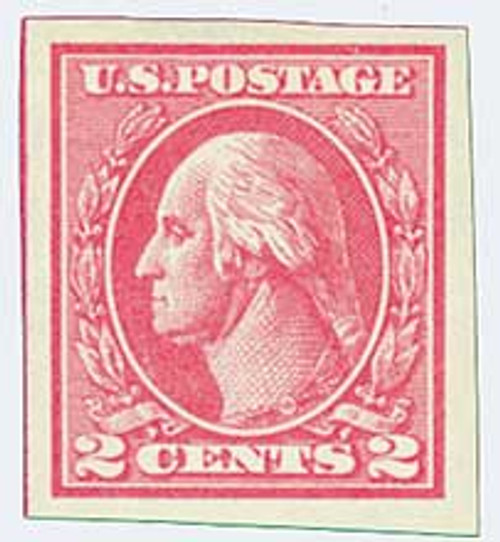

Offset Series of 1918-20

With the introduction of offset printing, the Bureau began its first experiment in mass production. Although millions of stamps were being printed each day with the conventional flat bed presses, this new method allowed for the printing plates to be produced automatically. Therefore, the plates could be prepared containing as many as 1600 stamps as compared to the old plates, which only had 400 per plate! These were the largest plates ever produced.

The process for making offset plates was basically performed with a camera and required no engraving or transfer rolls. An enlarged photograph of an engraved die proof was retouched to emphasize the shading lines and then photographed to create the “master negative.” This negative was placed in a special repeat machine, which photographically reproduced the positive impression on a glass plate. The image was repeated until the desired number of stamps was positioned on the plate.

From this glass plate, a celluloid negative, called a “mask,” was created, and at this stage, the plate numbers and guidelines were added. Finally, a positive impression was made on a steel plate, which was the actual plate used in printing.

Several differences distinguish stamps printed by offset from a flat plate stamp. The most noticeable is the lack of texture if one runs a finger lightly across the stamp’s surface. Because the ink lies flat on the paper, an offset stamp will feel very smooth, while the flat plate stamp, that is engraved, will have tiny grooves and ridges. Also, the ink used in offset printing is of a different quality and will vary in color when compared to the flat plate stamps. All stamps printed by the offset process will appear blurry and have less-defined images.

U.S. #536

1919 1¢ Washington

1919 1¢ Washington

Issue Date: August 15, 1919

Printed by: Bureau of Engraving and Printing

Method: Offset printing

Watermark: None

Perforation: 12.5

Color: Gray green

The Series of 1919 1¢ Washington produced by offset printing was the result of an experiment by the Bureau of Engraving and Printing. The Bureau was testing the new Rossback perforating machine. The experiment failed, as nearly half the sheets had to be destroyed because of major perforating errors. An estimated 1,386,000 stamps were issued.

Offset Series of 1918-20

With the introduction of offset printing, the Bureau began its first experiment in mass production. Although millions of stamps were being printed each day with the conventional flat bed presses, this new method allowed for the printing plates to be produced automatically. Therefore, the plates could be prepared containing as many as 1600 stamps as compared to the old plates, which only had 400 per plate! These were the largest plates ever produced.

The process for making offset plates was basically performed with a camera and required no engraving or transfer rolls. An enlarged photograph of an engraved die proof was retouched to emphasize the shading lines and then photographed to create the “master negative.” This negative was placed in a special repeat machine, which photographically reproduced the positive impression on a glass plate. The image was repeated until the desired number of stamps was positioned on the plate.

From this glass plate, a celluloid negative, called a “mask,” was created, and at this stage, the plate numbers and guidelines were added. Finally, a positive impression was made on a steel plate, which was the actual plate used in printing.

Several differences distinguish stamps printed by offset from a flat plate stamp. The most noticeable is the lack of texture if one runs a finger lightly across the stamp’s surface. Because the ink lies flat on the paper, an offset stamp will feel very smooth, while the flat plate stamp, that is engraved, will have tiny grooves and ridges. Also, the ink used in offset printing is of a different quality and will vary in color when compared to the flat plate stamps. All stamps printed by the offset process will appear blurry and have less-defined images.