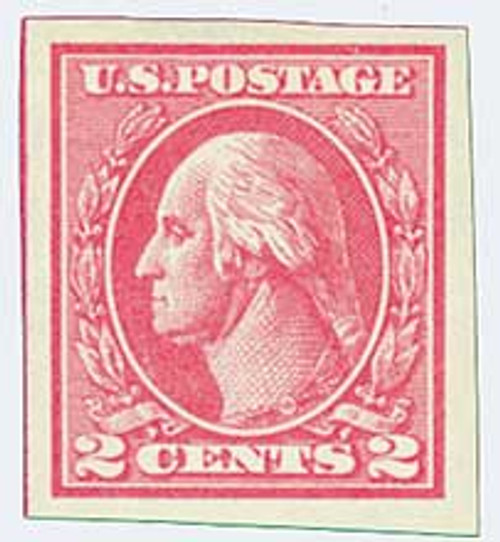

1920 2c Washington, imperf, type VI

# 534A - 1920 2c Washington, imperf, type VI

$95.00 - $975.00

U.S. #534A

1918-20 2¢ Washington

Type VI

1918-20 2¢ Washington

Type VI

Issue Date: July 26, 1920

Printed by: Bureau of Engraving and Printing

Method: Offset printing

Watermark: None

Perforation: None

Color: Carmine

The emergency demand for stamps of the 1¢ through 3¢ denominations that prompted the use of offset printing continued into 1921. The offset plates could be made rapidly and lasted longer than engraved plates. U.S. #534A was produced on 400, 800, and 1600 subject plates, and issued in sheets of 400.

Offset Printing Types IV-V-VA-VI-VII

The Series of 1918-20 2¢ Washington stamps had five distinct types, resulting from five separate photo negatives used to create the offset sheets. Eight areas on the stamp design reveal the differences – left-hand numeral “2,” toga button, toga rope, upper lip, nose shading, ribbon detail, leaves detail, and shading on top of Washington’s head.

Here is a summary of the primary differences:

Type V – Considered the standard by which other types are judged.

Type IV – Vertical lines in the toga button combine to form the word “DID,” with the first D backwards (others have 5 vertical lines). Laurel leaves and ribbon details not as well defined as in other types.

Type VA – Shading on the nose is incomplete, third line above nostril has only four dots, instead of six dots found in the other types.

Type VI – The line separating the two halves of left-hand numeral “2” is very wide.

Type VII – Above the upper lip there are four rows of three dots each. Other types have only two dots. Line separating halves in “2” wider than all other types except VI.

Type V – Considered the standard by which other types are judged.

Type IV – Vertical lines in the toga button combine to form the word “DID,” with the first D backwards (others have 5 vertical lines). Laurel leaves and ribbon details not as well defined as in other types.

Type VA – Shading on the nose is incomplete, third line above nostril has only four dots, instead of six dots found in the other types.

Type VI – The line separating the two halves of left-hand numeral “2” is very wide.

Type VII – Above the upper lip there are four rows of three dots each. Other types have only two dots. Line separating halves in “2” wider than all other types except VI.

Offset Series of 1918-20

With the introduction of offset printing, the Bureau began its first experiment in mass production. Although millions of stamps were being printed each day with the conventional flat bed presses, this new method allowed for the printing plates to be produced automatically. Therefore, the plates could be prepared containing as many as 1600 stamps as compared to the old plates, which only had 400 per plate! These were the largest plates ever produced.

The process for making offset plates was basically performed with a camera and required no engraving or transfer rolls. An enlarged photograph of an engraved die proof was retouched to emphasize the shading lines and then photographed to create the “master negative.” This negative was placed in a special repeat machine, which photographically reproduced the positive impression on a glass plate. The image was repeated until the desired number of stamps was positioned on the plate.

From this glass plate, a celluloid negative, called a “mask,” was created, and at this stage, the plate numbers and guidelines were added. Finally, a positive impression was made on a steel plate, which was the actual plate used in printing.

Several differences distinguish stamps printed by offset from a flat plate stamp. The most noticeable is the lack of texture if one runs a finger lightly across the stamp’s surface. Because the ink lies flat on the paper, an offset stamp will feel very smooth, while the flat plate stamp, that is engraved, will have tiny grooves and ridges. Also, the ink used in offset printing is of a different quality and will vary in color when compared to the flat plate stamps. All stamps printed by the offset process will appear blurry and have less-defined images.

U.S. #534A

1918-20 2¢ Washington

Type VI

1918-20 2¢ Washington

Type VI

Issue Date: July 26, 1920

Printed by: Bureau of Engraving and Printing

Method: Offset printing

Watermark: None

Perforation: None

Color: Carmine

The emergency demand for stamps of the 1¢ through 3¢ denominations that prompted the use of offset printing continued into 1921. The offset plates could be made rapidly and lasted longer than engraved plates. U.S. #534A was produced on 400, 800, and 1600 subject plates, and issued in sheets of 400.

Offset Printing Types IV-V-VA-VI-VII

The Series of 1918-20 2¢ Washington stamps had five distinct types, resulting from five separate photo negatives used to create the offset sheets. Eight areas on the stamp design reveal the differences – left-hand numeral “2,” toga button, toga rope, upper lip, nose shading, ribbon detail, leaves detail, and shading on top of Washington’s head.

Here is a summary of the primary differences:

Type V – Considered the standard by which other types are judged.

Type IV – Vertical lines in the toga button combine to form the word “DID,” with the first D backwards (others have 5 vertical lines). Laurel leaves and ribbon details not as well defined as in other types.

Type VA – Shading on the nose is incomplete, third line above nostril has only four dots, instead of six dots found in the other types.

Type VI – The line separating the two halves of left-hand numeral “2” is very wide.

Type VII – Above the upper lip there are four rows of three dots each. Other types have only two dots. Line separating halves in “2” wider than all other types except VI.

Type V – Considered the standard by which other types are judged.

Type IV – Vertical lines in the toga button combine to form the word “DID,” with the first D backwards (others have 5 vertical lines). Laurel leaves and ribbon details not as well defined as in other types.

Type VA – Shading on the nose is incomplete, third line above nostril has only four dots, instead of six dots found in the other types.

Type VI – The line separating the two halves of left-hand numeral “2” is very wide.

Type VII – Above the upper lip there are four rows of three dots each. Other types have only two dots. Line separating halves in “2” wider than all other types except VI.

Offset Series of 1918-20

With the introduction of offset printing, the Bureau began its first experiment in mass production. Although millions of stamps were being printed each day with the conventional flat bed presses, this new method allowed for the printing plates to be produced automatically. Therefore, the plates could be prepared containing as many as 1600 stamps as compared to the old plates, which only had 400 per plate! These were the largest plates ever produced.

The process for making offset plates was basically performed with a camera and required no engraving or transfer rolls. An enlarged photograph of an engraved die proof was retouched to emphasize the shading lines and then photographed to create the “master negative.” This negative was placed in a special repeat machine, which photographically reproduced the positive impression on a glass plate. The image was repeated until the desired number of stamps was positioned on the plate.

From this glass plate, a celluloid negative, called a “mask,” was created, and at this stage, the plate numbers and guidelines were added. Finally, a positive impression was made on a steel plate, which was the actual plate used in printing.

Several differences distinguish stamps printed by offset from a flat plate stamp. The most noticeable is the lack of texture if one runs a finger lightly across the stamp’s surface. Because the ink lies flat on the paper, an offset stamp will feel very smooth, while the flat plate stamp, that is engraved, will have tiny grooves and ridges. Also, the ink used in offset printing is of a different quality and will vary in color when compared to the flat plate stamps. All stamps printed by the offset process will appear blurry and have less-defined images.