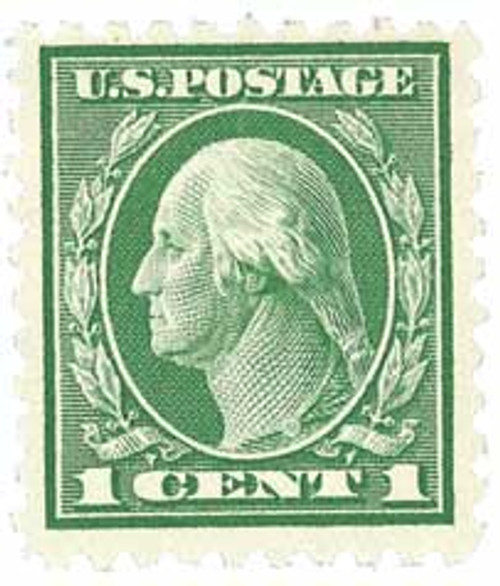

1914 9c Franklin, salmon red, single line watermark

# 432 - 1914 9c Franklin, salmon red, single line watermark

$8.50 - $1,050.00

U.S. #432

Series of 1914-15 9¢ Franklin

Series of 1914-15 9¢ Franklin

Issue Date: October 6, 1914

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 10

Color: Salmon red

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 10

Color: Salmon red

The Postal Service received complaints, particularly from heavy-user businesses, that sheets perforated 12 were too brittle and fell apart at the slightest touch. To strengthen the sheets, perforating machines were altered to 10 perforations per 2 centimeters, beginning with the 1914 issues.

Perforations Changed from “12” to “10”

When the 1908 series was issued, all stamps were perforated 12 gauge. Soon, both the public and postal workers began complaining that the perforations were too close, and the stamps could not be handled without coming apart. It wasn’t until 1910 that the Post Office Department began taking their complaints seriously. At this time, the Bureau began producing coils on a machine that would automatically wind the stamps into coiled rolls. They soon found the 12 gauge perforations were much too brittle to be used, since the stamps were continually becoming separated in the coiling process.

These events brought about the change to 8 1/2 gauge perforations. However, this produced stamps that were difficult to tear apart, consequently ripping the stamps. Again, the perforations were changed, this time to 10 gauge. While this change was fine for coiled stamps, it was unsuitable for sheets, which had a tendency to tear rather than separate at the perforations. Eventually, it was decided that 11 gauge perforations were suitable for sheets, while 10 gauge perforations were best for coils.

U.S. #432

Series of 1914-15 9¢ Franklin

Series of 1914-15 9¢ Franklin

Issue Date: October 6, 1914

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 10

Color: Salmon red

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Single line

Perforation: 10

Color: Salmon red

The Postal Service received complaints, particularly from heavy-user businesses, that sheets perforated 12 were too brittle and fell apart at the slightest touch. To strengthen the sheets, perforating machines were altered to 10 perforations per 2 centimeters, beginning with the 1914 issues.

Perforations Changed from “12” to “10”

When the 1908 series was issued, all stamps were perforated 12 gauge. Soon, both the public and postal workers began complaining that the perforations were too close, and the stamps could not be handled without coming apart. It wasn’t until 1910 that the Post Office Department began taking their complaints seriously. At this time, the Bureau began producing coils on a machine that would automatically wind the stamps into coiled rolls. They soon found the 12 gauge perforations were much too brittle to be used, since the stamps were continually becoming separated in the coiling process.

These events brought about the change to 8 1/2 gauge perforations. However, this produced stamps that were difficult to tear apart, consequently ripping the stamps. Again, the perforations were changed, this time to 10 gauge. While this change was fine for coiled stamps, it was unsuitable for sheets, which had a tendency to tear rather than separate at the perforations. Eventually, it was decided that 11 gauge perforations were suitable for sheets, while 10 gauge perforations were best for coils.