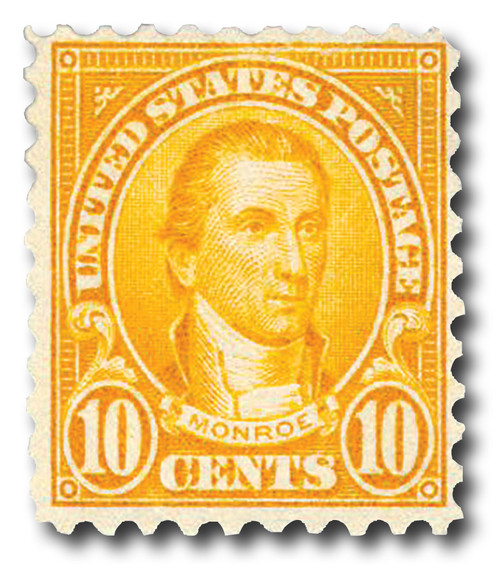

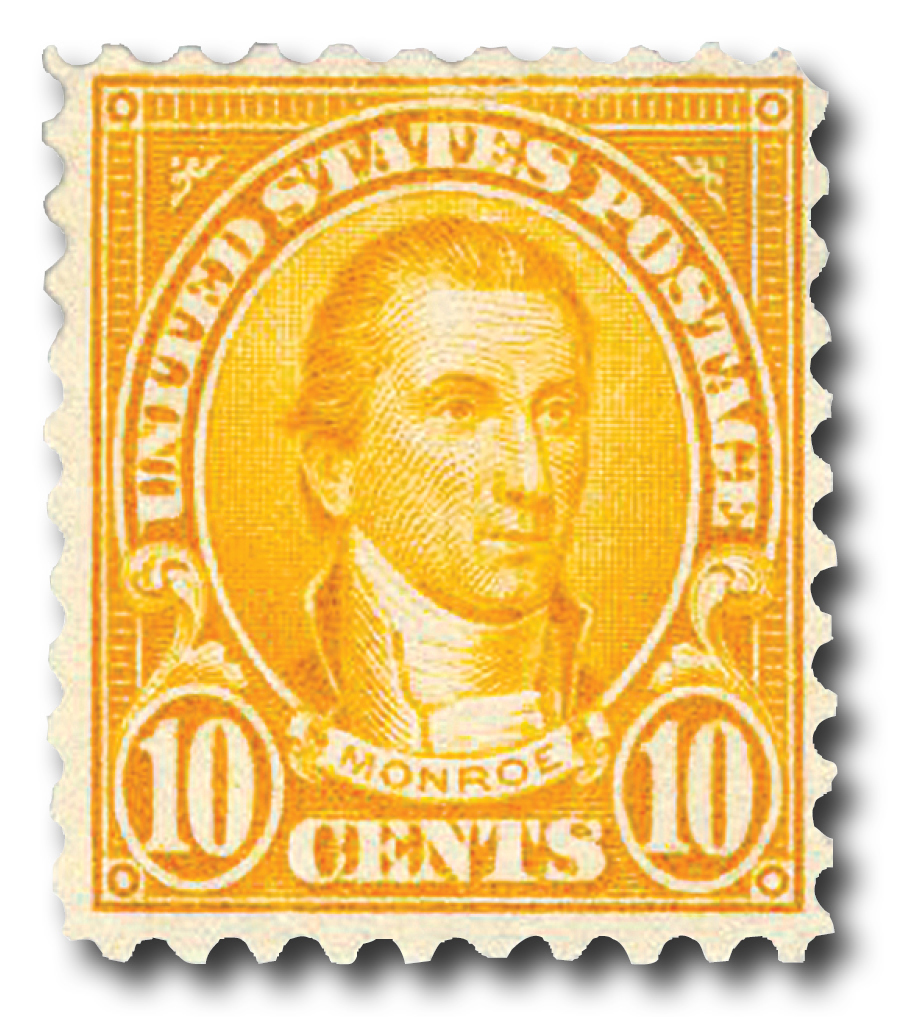

# 591 - 1925 10c Monroe, orange

U.S. #591

Series of 1923-26 10¢ James Monroe

First City: Washington, D.C.

Quantity Issued: 129,967,000

Printed by: Bureau of Engraving and Printing

Printing Method: Rotary Press

Perforation: 10

Color: Orange

Washington’s Unanimous Election

The Monroe Doctrine

On December 2, 1823, President James Monroe introduced the foreign policy doctrine that bears his name.

The last President of the “Virginia Dynasty” (four out of the first five Presidents were from Virginia), James Monroe was a levelheaded and respected force throughout his political career. He participated in the ratification of the US Constitution, negotiated the Louisiana Purchase, and implemented the Missouri Compromise. He diligently worked to maintain peace and unity, and to keep America free from foreign oppression.

In 1817, Monroe selected John Quincy Adams as his Secretary of State. In this role, Adams helped settle a boundary dispute with England and added Florida to the US. Following the First Seminole War, in which Andrew Jackson pushed Seminole Indians south and removed one governor and chose another, most of Washington believed Jackson had exceeded his authority. But Adams argued that since Spain was unable to control its territories, the US needed to defend itself. Adams met with Spanish foreign minister Luis de Onís to establish the Adams-Onís Treaty, which made Florida a territory of the US and settled border disputes dating back to the Louisiana Purchase.

In response to this, neighboring European countries issued threats of an alliance to help Spain retake control of its former territories in the Americas. Monroe’s friends and colleagues Thomas Jefferson and James Madison urged him to accept the British offer of an alliance against France and Spain. Instead, Monroe chose to follow the advice of John Quincy Adams, who believed America should not be influenced by European intrusions. Adams emphasized that American policy was only to serve as moral support for independence movements, but not armed intervention. Though it bears Monroe’s name, Adams wrote the Monroe Doctrine.

On December 2, 1823, President Monroe addressed Congress with what would later be called the Monroe Doctrine. President Monroe declared that “…We owe it, therefore, to candor and to the amicable relations existing between the United States and those powers to declare that we should consider any attempt on their part to extend their system to any portion of this hemisphere as dangerous to our peace and safety. With the existing colonies or dependencies of any European power, we have not interfered and shall not interfere.”

With this speech, Monroe declared to the major world powers that America would no longer be accessible to European colonization. He also warned against any European nations attempting to impress political influence in America. Monroe also stressed that America would stay out of European affairs, and expected the equivalent from them.

Several Presidents have invoked the doctrine over the years, making it the cornerstone of America’s foreign policy. Click here to see how the doctrine has been used over time.

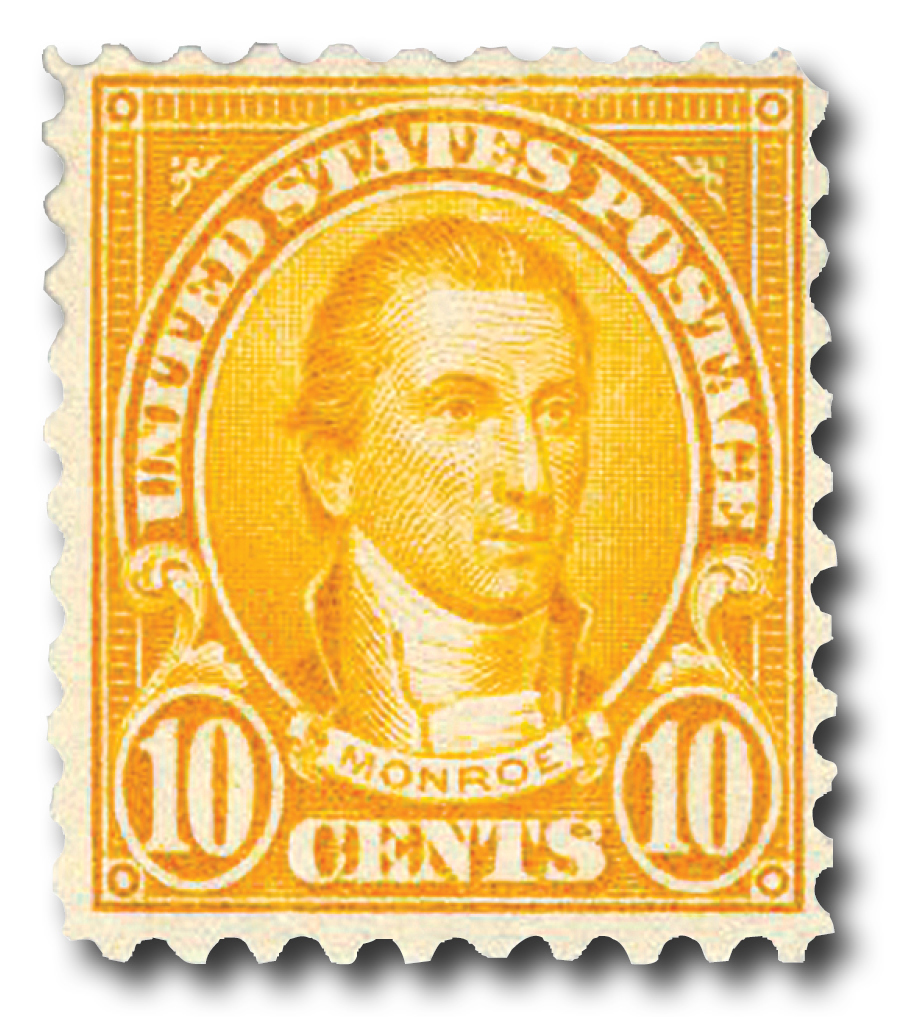

U.S. #591

Series of 1923-26 10¢ James Monroe

First City: Washington, D.C.

Quantity Issued: 129,967,000

Printed by: Bureau of Engraving and Printing

Printing Method: Rotary Press

Perforation: 10

Color: Orange

Washington’s Unanimous Election

The Monroe Doctrine

On December 2, 1823, President James Monroe introduced the foreign policy doctrine that bears his name.

The last President of the “Virginia Dynasty” (four out of the first five Presidents were from Virginia), James Monroe was a levelheaded and respected force throughout his political career. He participated in the ratification of the US Constitution, negotiated the Louisiana Purchase, and implemented the Missouri Compromise. He diligently worked to maintain peace and unity, and to keep America free from foreign oppression.

In 1817, Monroe selected John Quincy Adams as his Secretary of State. In this role, Adams helped settle a boundary dispute with England and added Florida to the US. Following the First Seminole War, in which Andrew Jackson pushed Seminole Indians south and removed one governor and chose another, most of Washington believed Jackson had exceeded his authority. But Adams argued that since Spain was unable to control its territories, the US needed to defend itself. Adams met with Spanish foreign minister Luis de Onís to establish the Adams-Onís Treaty, which made Florida a territory of the US and settled border disputes dating back to the Louisiana Purchase.

In response to this, neighboring European countries issued threats of an alliance to help Spain retake control of its former territories in the Americas. Monroe’s friends and colleagues Thomas Jefferson and James Madison urged him to accept the British offer of an alliance against France and Spain. Instead, Monroe chose to follow the advice of John Quincy Adams, who believed America should not be influenced by European intrusions. Adams emphasized that American policy was only to serve as moral support for independence movements, but not armed intervention. Though it bears Monroe’s name, Adams wrote the Monroe Doctrine.

On December 2, 1823, President Monroe addressed Congress with what would later be called the Monroe Doctrine. President Monroe declared that “…We owe it, therefore, to candor and to the amicable relations existing between the United States and those powers to declare that we should consider any attempt on their part to extend their system to any portion of this hemisphere as dangerous to our peace and safety. With the existing colonies or dependencies of any European power, we have not interfered and shall not interfere.”

With this speech, Monroe declared to the major world powers that America would no longer be accessible to European colonization. He also warned against any European nations attempting to impress political influence in America. Monroe also stressed that America would stay out of European affairs, and expected the equivalent from them.

Several Presidents have invoked the doctrine over the years, making it the cornerstone of America’s foreign policy. Click here to see how the doctrine has been used over time.